Zero Volume Air Chambers

This prototyping technique uses simple tools to create a network of inflatable bladders of abitrary geometry in thin elastomers. Â There are five basic steps that include

Step 1: Design the mask. Â The video presents a CAD drawing of a serpentine channel. Â The mask can be paper or a thin film. Â In this particular example, the mask for the serpentine channel was laser cut from paper.

Step 2: Laser cut mask and apply mold release. The video presents the mask applied on top of an already cured thin layer of silicone.

Step 3: Remove the mask. Under the right lighting, mold release is visible as it defines the shape of the serpentine channel.

Step 4: Pour a thin layer of silicone on top. Â Any portion of the first layer of silicone covered by the mold release will not bond to the second layer. Â This defines the air chamber.

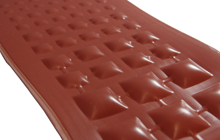

Step 5: Inflate. Â Once the second layer of polymer has cured the channel can be inflated.

Prototyping tips:

- Choose a mask material that conforms to the surface of the polymer. Â Paper works, but thin films such as vacuum bagging films are better.

- The mask can contain island features (e.g. creating an inflated ring), but will require manual placement.

- In my experience, air channels narrower than 2mm are hard to create.

- The thinner the material you can pour the more pronounced the inflation.

- The process can be repeated to stack multiple layers.

- The stronger the bond between the two polymer layers the better. Â Poor bonds and features that are too close together can result in delamination.

The potential applications of this prototyping technique include building surfaces with tunable stiffness, shape morphing surfaces and textures, and microfluidics. Â In a recent publication, this process combined fiber reinforcements to create flat pneumatic artificial muscles to support active knee motions (paper link below).